At BECS, we aren’t just consultants, but scientists. This includes harnessing the latest and greatest technologies, like WUFI Technology, to assist in identifying current issues and predicting future complications with the building envelope.

Recently, our experts have been utilizing WUFI Technology. What is WUFI, you ask? In technical terms, WUFI is a German acronym that stands for “Wärme-und Feuchtetransport instationär”. This translates in English to “Transient Heat and Moisture Transport”. We use this software to calculate the coupled heat and moisture transfer in building components. WUFI software achieves realistic calculations of the transient hygrothermal behavior of multi-layer building components exposed to natural climate conditions. (Hygrothermal = Heat + Moisture)

Scenarios

We can implement this technology in many different scenarios, such as:

- Calculating the drying time of masonry with trapped construction moisture

- Evaluating the danger of interstitial condensation. This a type of condensation that may occur within an enclosed wall, roof or floor cavity structure, which can create dampening.

- Determining the influence of driving rain on exterior building components

- Assessing the effect of repair and retrofit measures

- Analyzing the hygrothermal performance of roof and wall assemblies under unanticipated use or in different climate zones.

- Predicting the hygrothermic conditions of a structure before construction begins or before any significant alterations are made (roof, wall, exterior components)

- Mitigating the risk of moisture damage (mold, dry rot, corrosion, etc.)

WUFI Projects

In real-world practice, BECS is currently working on two WUFI projects with Architects for buildings in Philadelphia, PA. The first is a new construction project for a new building where we are analyzing different insulation options for wall systems. We are providing feedback and recommendations on the differences in hygrothermal performance between options.

The second is a retrofit of an old Navy barracks where they are re-purposing the mass masonry wall building into a hotel and are adding air and vapor barriers, insulation on the inside (looking at performance differences in different insulation options), and new interior walls with different finishes.

So, how does WUFI work? To summarize at a high-level, WUFI operates in a few steps:

- Create a case in the software by entering in info

- Select the layers of assembly and adjust parameters to match materials used

- Factor in other details such as climate, weather conditions, wind speed, etc. (More info entered = more precise model)

- Run the simulation (WUFI will solve all the partial differential equations for determining moisture and heat flow hour by hour during the course of the day)

- Interpret Data (WUFI will reveal how each layer of the wall assembly will react to moisture and temperature over time)

Sounds easy – right? Not so fast. While inputting the necessary data to run a simulation isn’t very daunting, the challenge to using a complex tool like WUFI is understanding the model output.

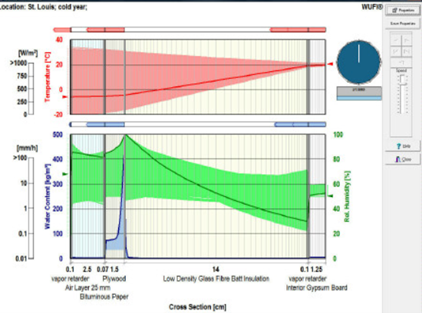

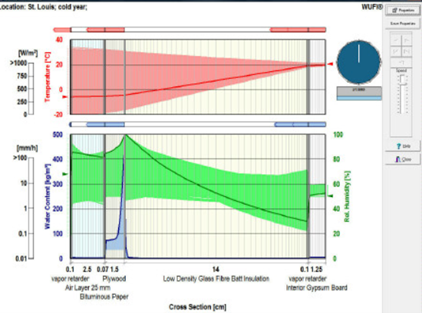

This is an example of a WUFI “film” showing heat, moisture, and humidity transport through the layers of the wall/woof system over a given simulation period.

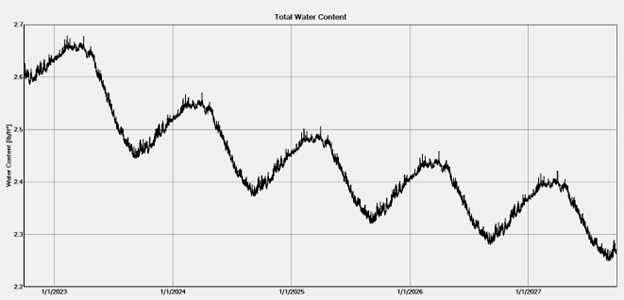

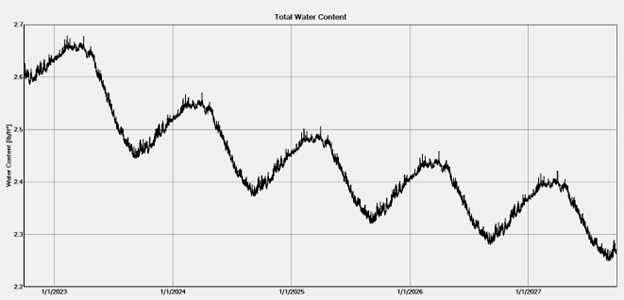

This graph shows total water content throughout the entire system over a given simulation period. You typically start the simulation modeling an initial water content and relative humidity based on each material layer to ensure they system dries out over time. This graph depicts the total water content is drying out overtime, which is exactly what you want to see.

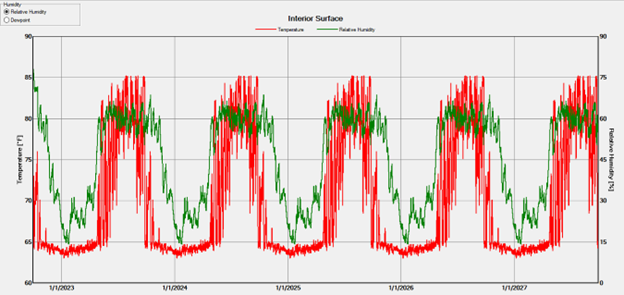

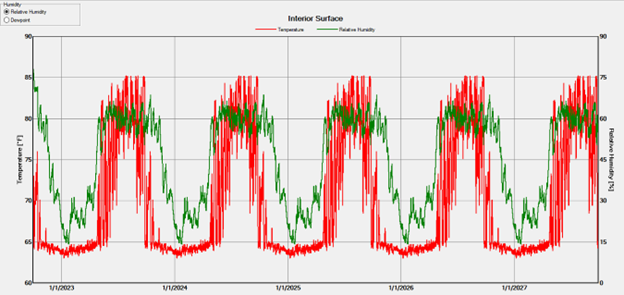

Lastly, this graph depicts temperature and relative humidity over time. Relative humidity of 80% or higher is a dangerous level for creating moisture damage in components within the assembly.